now offers a variety of circuit board fabrication to its capabilities. Starting from single to dual sided flex circuits, to Rigid board and Rigid flex Circuits.

We have built a good reputation for providing Quik-Turn™ assembly and now we are taking it another step farther to provide the same Quik-Turn™ delivery for PCB’s and Flex circuits.

Our Mission is taken very seriously and when it comes to delivery, we strive for perfection and that is why our customers are coming to us for even bare board fabrication.

Because understanding boards really well is part of our life line, we can assist you in all areas of your design. From a Design on a napkin, to Schematic Capture and then to Board Layout, we can provide assistance to your design team in all levels of service. Think of us as being an extension to your internal services by providing Design and full layout services prior to ordering your boards.

By offering nights and weekend services we get the job done quicker than you can do it internally. That's our pledge to you. All you need to do is ask about how we can serve you. Let us take your multilayer PCB from design to reality.

Printed circuit board technologies we fabricate:

Standard FR4 and Hi-Temp FR4, Flex and Rigid-Flex

DuPont, Rogers, Shin-Etsu

RF/Microwave/High Speed Hybrids

- Rogers FR4 with Roger, Arlon,Taconic

- Taconic FR4 with heavy metal copper

- Arlon

- Getek

- Polyimide

Services: Lead Times

FR4 (1-8 layers): 1 day - 2 weeks turn

FR4 (10-32 layers): 2 days - 3 weeks turn

Flex (1-4 layers): 1 day - 2 weeks turn

Flex (6-20 layers): 5 days - 3 weeks turn

PC Prototype and Small to Medium Sized Runs Fabrication and Assembly

Today's high-tech company demands a variety of PCB capabilities from their suppliers. Dimation offers a range of single layer and multilayer PCB fabrication, including:

Standard/hi-temp FR4

Flex/rigid-flex (DuPont, Rogers, Shin-Etsu)

RF/microwave/high-speed (Rogers, Taconic, Arlon, Getek, Polyimide)

Hybrids (FR4 with Roger/Arlon/Taconic, FR4 with heavy metal copper)

With a proven commitment to customer service, Dimation sets the standard for PCB fabrication for any company located in the midwest and beyond--and when businesses need total turn-key services, Dimation also offers printed circuit board design and assembly services.

Dimation now offers a variety of circuit board fabrication to its capabilities. Starting from single to dual sided flex circuits, to Rigid board and Rigid flex Circuits.

We have built a good reputation for providing Quik-Turn™ assembly and now we are taking it another step farther to provide the same Quik-Turn™ delivery for PCB’s and Flex circuits.

We take our Mission very seriously and when it comes to delivery, we strive for perfection and that is why our customers are coming to us for even bare board fabrication.

At Dimation, we understand boards really well and can assist you in all areas of your design.

From a Design on a napkin, to Schematic Capture and then to Board Layout, we can provide assistance to your design team in all levels of service. Think of us as being an extension to your internal services by providing Design and full layout services prior to ordering your boards.

By offering nights and weekend services we get the job done quicker than you can do it internally. That's our pledge to you. All you need to do is ask about how we can serve you.

- Assembly Support -

- Consignment

- Turnkey

- Computer Modelling and Analysis

- Design Layout Service

- DFM and Reliability

- Engineering / Application Support

- Interconnect Solutions

- Termination Methods

- Material Selection and Construction

Services

Capabilities

- Panel Size: 18 X 24 max; 12 X 18 min

- Layer Count: 24 max

- Hole Diameter: .004 drilled

- Line Width & Spacing: .002 min

- Dielectric Thickness Mins: .001 Kapton, .002 (FR-4)

- Board Thickness: .125 max

- Soldermask Clearance: .003 min

- 1:1 With LDI Mask for Mask Defined Comps

- UL approved unpierced area: 4"

- Solder Finishes

- HASL

- Immersion Silver, Gold, Tin

- Electrolytic Gold (Soft Bondable)

- ENEPIG

- OSP

- Laser Drill

10- Up Days

(STD Turn Times)

(Includes Expedite Fee’s)

2 - 3 Days

5 - 7 Days

24 Hours

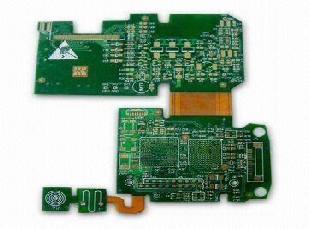

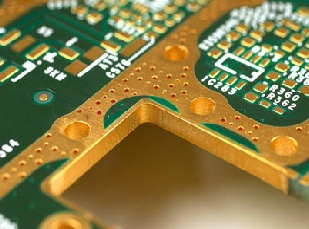

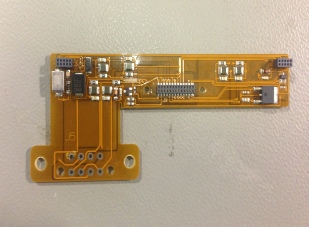

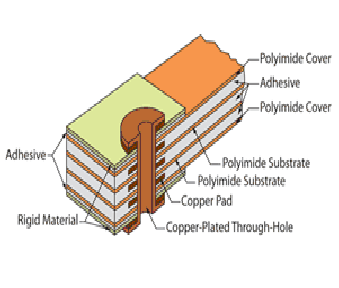

Dimation offers Rigid flex printed circuit boards using a combination of flexible and rigid board technologies in an application. Most rigid flex boards consist of multiple layers of flexible circuit substrates attached to one or more rigid boards externally and/or internally, depending upon the design of the application. The flexible substrates are designed to be in a constant state of flex and are usually formed into the flexed curve during manufacturing or installation.

Rigid flex designs are more challenging than the design of a typical rigid board environment, as these boards are designed in a 3D space, which also offers greater spatial efficiency. By being able to design in three dimensions rigid flex designers can twist, fold and roll the flexible board substrates to achieve their desired shape for the final application's package.

Process Capabilities

- Panel Size: 18 X 24 max; 12 X 18 min

- Layer Count: 30 max

- Hole Diameter: .004 drilled

- Line Width & Spacing: .002 min

- Dielectric Thickness Mins:

- .001 Kapton, .002 (FR-4)

- Board Thickness: .125 max

- Aspect Ratio: 10:1

- Soldermask Clearance: .003 min

- 1:1 With LDI Mask for Mask Defined Comps

- UL approved unpierced area: 4"

Materials Availlable

- DuPont Pyralux:

- DuPont AP Copper Clad Laminates

- DuPont LF and FR

- Coverlays and Bonding Plys

Hitachi:

- Polyimide laminates

- Polyimide no-flow prepreg

Arlon:

- Laminates and no-flow prepregs

Isola:

- Laminates and no-flow prepregs

2 - 3 Weeks

4-5 Weeks

(STD Turn Times)

(Includes Expedite Fee’s)

8-10 Days

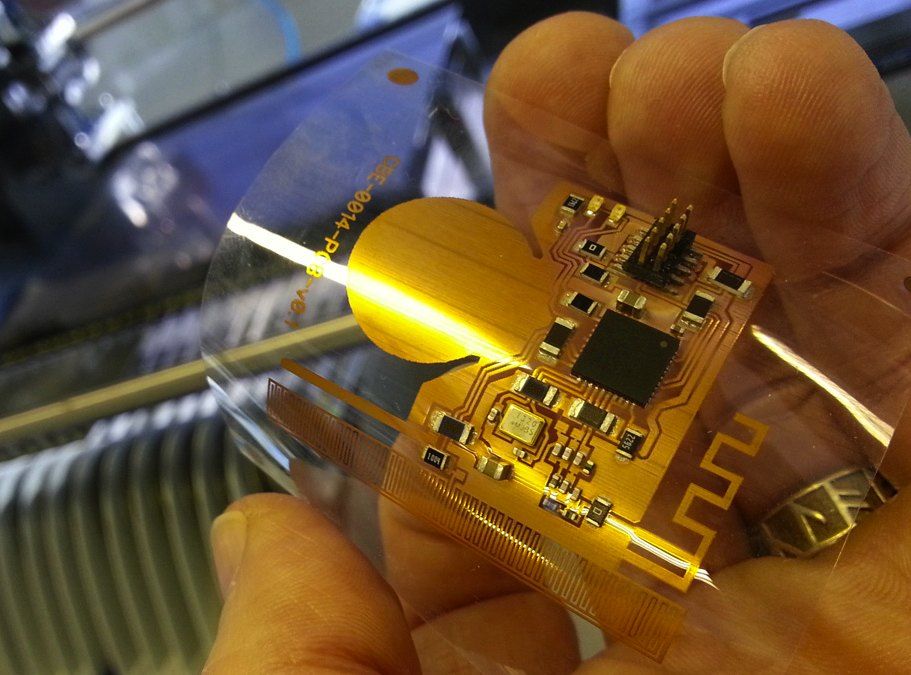

Dimation offers a variety of flex circuit capabilities, including single or double sided circuitry to multilayer technology up to 6 layers. We also have multiple material substrates and adhesives to choose from, along with surface finishes and treatments.

Stiffeners can also be added to reinforce selective areas of the flexible circuitry for component support durability and mounting.

Process Capabilities

Single or Double Sided Flex: Polyimide, Polyester

Multilayer Flex up to 8 layers

Multilayer Rigid-Flex up to 20+ layers (rigid area)

Lines and Spaces: down to 0.003"

Installation of Connectors, Pins, Contacts, etc.

MD & PTH Component Assembly available

Stiffener Supported Areas (using FR-4, Polyimide, etc.)

Blind & Buried Vias

Controlled Impedance

Selective Adhesives, PSAs and Thermally bonded

EMI / RF Shielding: Copper, Silver Ink & Shielding films

Circuits up to 24" in length

Flexible Circuit Materials

Substrates

Kapton: Polyimide 1/2 – 5 mils

Mylar: Polyester 2 - 5 mils

Epoxy

Teflon

Copper

Half Hard Electro-deposited

Flex Circuit Adhesives

Modified Acrylic

Modified Epoxy

Pressure Sensitive (PSA)

Solder Mask / Coverlay

Kapton Coverlay 1/2 mil to 5 mils

Polyester Coverlay 1 mil to 3 mils

Photoimageable Coverlay

Soldermask

Surface Treatment & Finishes

Hard or Soft Gold

Hot Air Level (H.A.L.)

Carbon Printing

Screen Print Solder Mask

Silver

Types of Flex Circuits

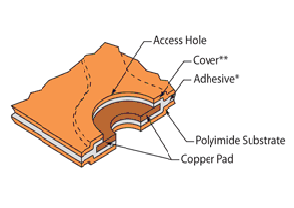

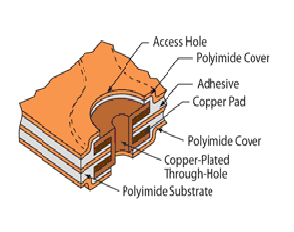

Single-Layer Flex Circuit

IPC 6013 - Type 1

One conductive layer, either bonded between two insulating layers or uncovered on one side.

Stiffeners, pins, connectors, components, are optional.

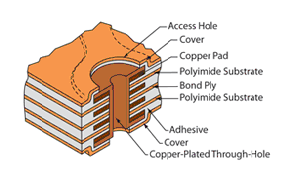

Multi-Layer Flex Circuit

IPC 6013 - Type 3

Three or more flexible conductive layers with flexible insulating layers between each one; outer layers may have covers or exposed pads.

Plated through-holes provide connection between layers.

Controlled impedance possible.

Double-Sided Flex Circuit

IPC 6013, - Type 2

Two conductive layers with an insulating layer between; outer layers may have covers or exposed pads.

Plated through-holes provide connection between layers.

Stiffeners, pins, connectors, components are optional.

Rigid-Flex Circuit

IPC 6013 - Type 4

Two or more conductive layers with either flexible or rigid insulation material as insulators between each one; outer layers may have covers or exposed pads.

Rigid-flex has conductors on the rigid layers, which differentiates it from multi-layer circuits with stiffeners. Plated through-holes extend through both rigid and flexible layers (with the exception of blind and buried vias). Rigid-flex costs more than a standard circuit with stiffeners.

10 Days

2-3 Weeks

4-5 Weeks

(STD Turn Times)

(Includes Expedite Fee’s)

3-5 Days

Dimation Inc. © 2018

An AS9100 Service provider

ITAR Registered. We take it serious about being compliant!